Eddy Current Array Pipe Inspection

IXT have recently added to their testing arsenal the flexible eddy current array probe which is suited to a broad range of applications.

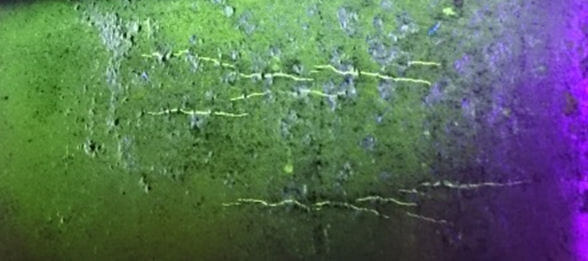

Pipeline & Piping Stress Corrosion Cracking (SCC) Inspection

The probe is scanned across the surface and can detect

stress corrosion cracking in any direction through coatings as thick as 2 mm.

Though the results are comparable, eddy current array technology is much less time consuming and labour intensive than penetrant

or magnetic particle inspection.

With eddy current array

inspection, you can eliminate costly and complicated

procedures, such as paint and coating removal.

This is a

green solution with no mineral sands or paint particle

cleanup, no air quality issues, no noise, and in addition no

need to apply a white background coating for magnetic

particle testing.

Cost savings gained by no blasting, no

repainting , no background paint to apply, can easily amount

to tens of thousands of dollars for a large project.

The new versitile eddy current array probe with interchangeable wedges fits a wide range of pipe sizes and can quickly scan small areas or bends.

With the new continuous mode, scan imagery is revealed in real time with a constant results stream.

This compliments the semi-automated chain scanner for straight lengths with full recording capability and without having to remove the coating.

For more information see www.ixt.com.au