Gear Test

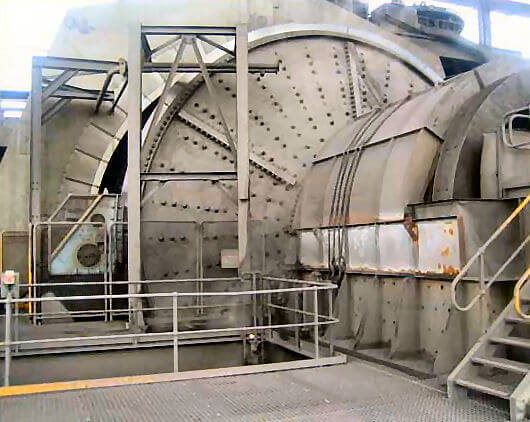

Girth gears, pinions, bull gears and sugar mill drive trains are critical components and need to have regular inspection so operators know they're in serviceable condition and often as an insurance requirement.

The Gear test team use the latest Eddy Current Array (ECA) and Phased Array Ultrasonic Testing (PAUT) equipment to provide the best girth gear inspection service in Australia.

Eddy Current Array (ECA) Gear Testing

- Eddy Current Array (ECA) testing provides 100% coverage of root and load face in one pass and ideally suited for mill and kiln girth gears testing with two probes able to cover most sizes.

- For smaller gears a flexible probe like a piece of thick vinyl can conform to any gear shape required.

- In most cases removal of lubricant isn't required.

- Any cracking is immediately detected and sized.

- We can complete the inspection on your ball mill, rod mill or SAG mill in one shift and get it back into production fast.

- If you don't have a full shift available we'll come back and get all teeth inspected over several shutdowns.

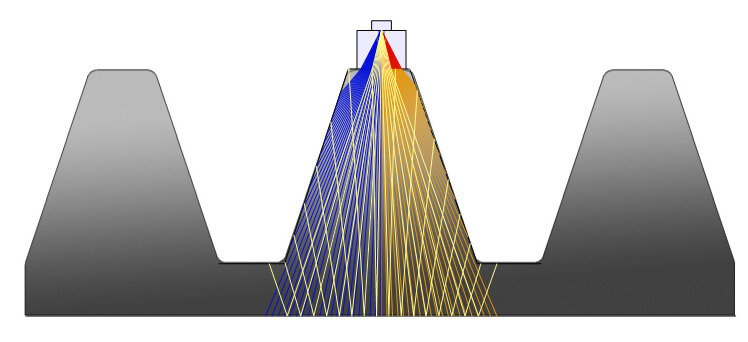

Phased Array Ultrasonic Testing (PAUT)

- When a gear is cracked you need to know if you can keep operating while you get a plan into action.

- Phased Array Ultrasonic Testing can measure the depth of cracking where all other methods fail and give you the information to make a decision.