Eddy Current Array (ECA)

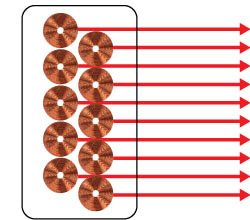

Eddy current array (ECA) technology for gear testing provides the ability to electronically drive and read several eddy current sensors positioned side by side in the same probe assembly.

ECA is the supercharged version of Eddy Current Testing (ECT) and although the term Phased Array Eddy Current is commonly used in error, the method actually uses Multiplexing where individual coils are excited at different times to improve cracking detection.

The gear probe has 32 coils arranged on the face and end so that they scan the root and load face of the tooth simultaneously and the huge effort of complete grease removal isn't required.

This single scan technique makes inspection of large girth gears fast and without missing anything.

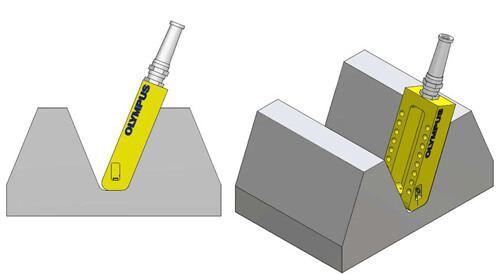

Eddy current array (ECA) technology for gear testing incorporates several traditional bridge or reflection (driver-pickup) probe coils in order to achieve a much larger coverage in a single inspection pass. Additionally, each ECA probe model is carefully designed to maintain a high probability of detection of a targeted defect range all along the probe length. With the OmniScan® MX ECA, we can use ECA probes at fast manual-inspection speeds, offering a powerful and productive inspection with colour representation and archiving capability.

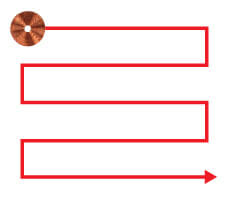

Single Coil Raster Scanning is either slow or misses most of the surface.

Array Probes provide multiple coils to scan a wide area in a single sweep without missing anything.

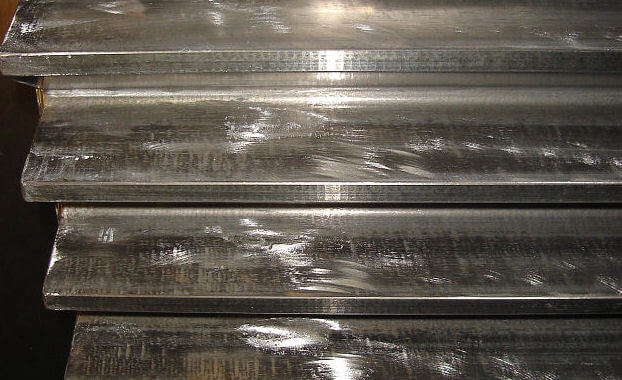

Inspection through Thin Coatings and Grease

Eddy current testing (ECT) technology works on the principle of magnetic coupling of a probe sensor (coil) close to a test specimen (conductive material, ferromagnetic or non-ferromagnetic), generating eddy currents inside the test specimen, and displaying signals on the instrument’s impedance plane. With eddy current technology, you can detect defects through thin coatings (such as paint or grease), as long as the distance from the probe to the metal is kept reasonably low—typically in the order of 0.5 mm to 2.0 mm.

As eddy current array and ECT technology share the same basic principles (and physics), it can also perform inspections through paint and grease while offering all advantages of ECA, including large coverage, fast scanning, high probability of detection and colour imaging.

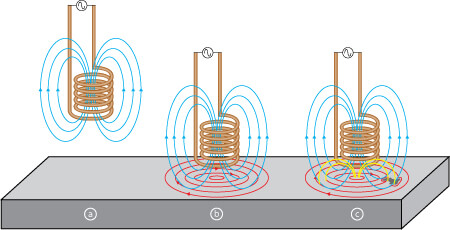

Probes used to perform eddy current inspections are made with a copper wire wound to form a coil. The coil shape can vary to better suit specific applications.

- The alternating current flowing through the coil at a chosen frequency generates a magnetic field around the coil.

- When the coil is placed close to an electrically conductive material, an eddy current is induced in the material.

- If a flaw in the conductive material disturbs the eddy current circulation, the magnetic coupling with the probe is changed and a defect signal can be read by measuring the coil impedance variation.